Volume determination

The main core of the system is the volume determination section. The hardware of this section is the 3D imaging system which would be installed along and above the trucks’ moving path. Stereo cameras (3D vision) or laser curtain can be used for this task.

Each 3D imaging system in stereo technique contains two cameras which are precisely calibrated with each other and through the combination of the images of these cameras, the depth of each pixel of the image can be accurately extracted. Also this information is useful for measuring the volume of objects in the image.

A set of stereo cameras which are installed above the trucks’ path, take the 3D image of the top part of the vehicle and in this way, all of the roughness or ups and downs in the load would be recorded in the software. In another word through 3D imaging from above, there would be no limitation for the roughness of top surface in the load and all of the ups and downs in the load would be intelligently involved in the calculations.

The second imaging set is installed on the sides of trucks’ path and it detects the height of the load part of the vehicle through taking a 3D profile from sides of the trucks. Therefore, the above profile of the load is measured by the above stereo camera and the final depth of the load is measured by the side camera.

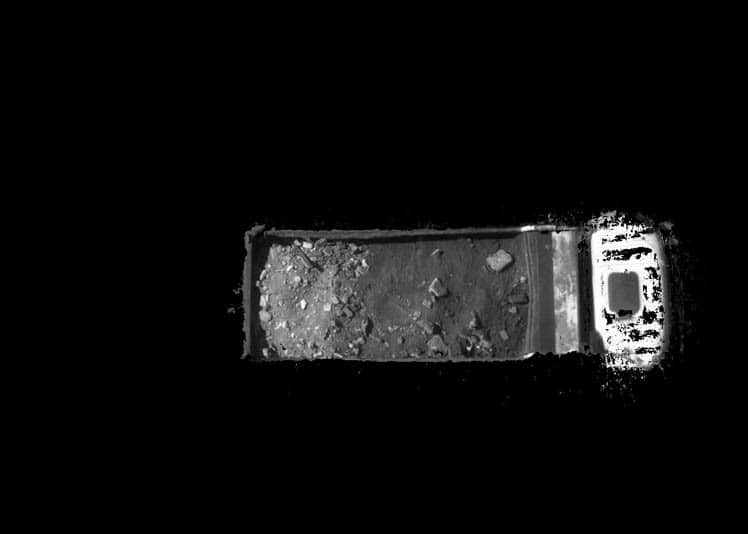

Processing levels are demonstrated below:

Left and right camera images

Through the combination of images, integrated image and depth information would be extracted which is demonstrated below:

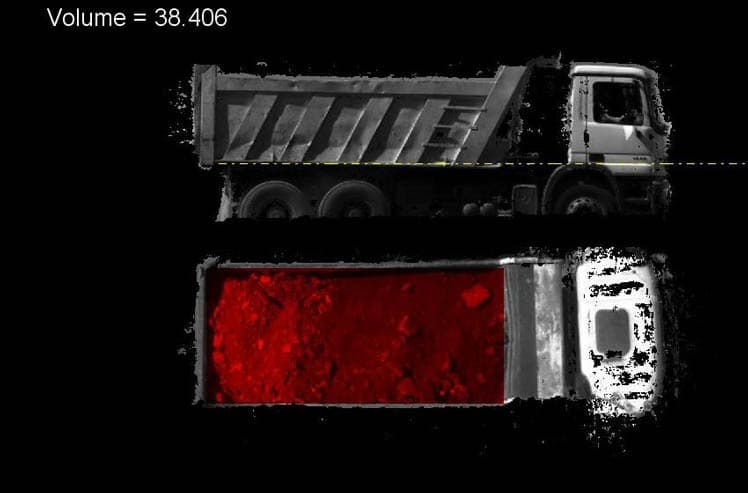

Intelligent detection of load section

After recognizing the around environment of the load section and by having the 3D curve of the above section of load section, load volume would be calculated through above 3D imaging and also applying mathematical calculations. Some sample of this system’s performances are shown in the pictures below: