Iota Sorter

Large Fruits Sorter

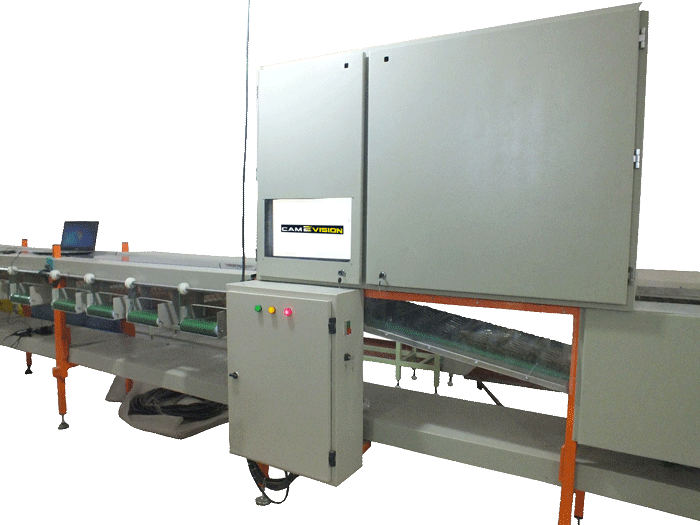

The Iota sorter is a sorting machine with specific dimensions and characteristics suitable for the production line, which the various parts of the machine including feeding, image processing, and the outputs are intertwined. This machine is the best sorter machine for sorting large fruits. Especially if you don't lack enough space and infrastructure in the workplace and intend to have more than 8 outputs, this device will meet all your needs.

The Iota sorter can handle a maximum of 6 fruits per second for each line, which, for a fruit such as cucumbers, with an average weight of 120 g, the machine will be able to sort about 3 tons per hour. However, the number of machine lines can easily be increased to 4 lines and this will increase the capacity of the machine to 12 tons per hour. It is worth mentioning that in this system the number of outputs is designed according to the customer’s needs.

The functionality of this system is such a way that the fruits are automatically or manually put on the longitudinal conveyers of the machine and pass through the imaging section as the conveyer moves. After processing the images, all fruits would be categorized into different, user pre-defined categories. Under these conditions, by passing in front of the output of each category, the related operator will be activated and push the fruit onto the related conveyer. The outputs are located below the main conveyer. The fruit would be transported to the corresponding output basket by this conveyer and will be manually or automatically placed in the fruit basket.

It should be noted that the machine weighs each fruit basket and, along with other information, including the fruit garden, the line manager, the fruit specifications within the basket, the time and place of the fruit, and other information on a label in 2D text and barcode printing. And the user attaches it to the box. This information is very important in managing the line and tracking possible consumer complaints.

It should be noted that the machine measures the weight of each fruit basket and prints it on a label in text and 2D barcode together with other information including the fruit’s garden, the line manager, the fruit characteristics within the basket, the sorting time and place etc. and the user attaches it on the box. This information is very important for managing the line and tracking possible consumer complaints.

The performance of the machine:

- Appropriate for sorting all kinds of fruits, especially large fruits

- Sorting based on size and dimension (length, diameter, large shape, curvature, etc.)

- Sorting based on appearance defects (stain, incision, scratch, etc.)

- Color-based sorting

- Weight-based sorting

- The ability of sterilization with UV radiation

- Image processing sorting capability in different optical spectra

The machine features:

- The ability of observing all of the fruit sides by the sensors

- Non-pneumatic functionality

- Low noise operation

- No need to water

- The possibility of designing a washable machine

- The possibility of customizing the stations with larger ones

- Applying the principles of ergonomics and ordering the work process

- The possibility of selecting the number of outputs

- 24/7 functionality

- Industrial standard

- User-friendly interface

The machine advantages:

- Economic value-added by sorting the fruit

- Reducing the production costs

- Reduction of wasted materials

- Reduction of dissatisfaction or complaints and product return

- Permanent and repeatable quality

- Production line Output and input precise controlling (production line management).

- Products health increase

- Production line analysis and reports

- The possibility of product tracking