Sampi Sorter. Based on artificial intelligence and image processing ϡ

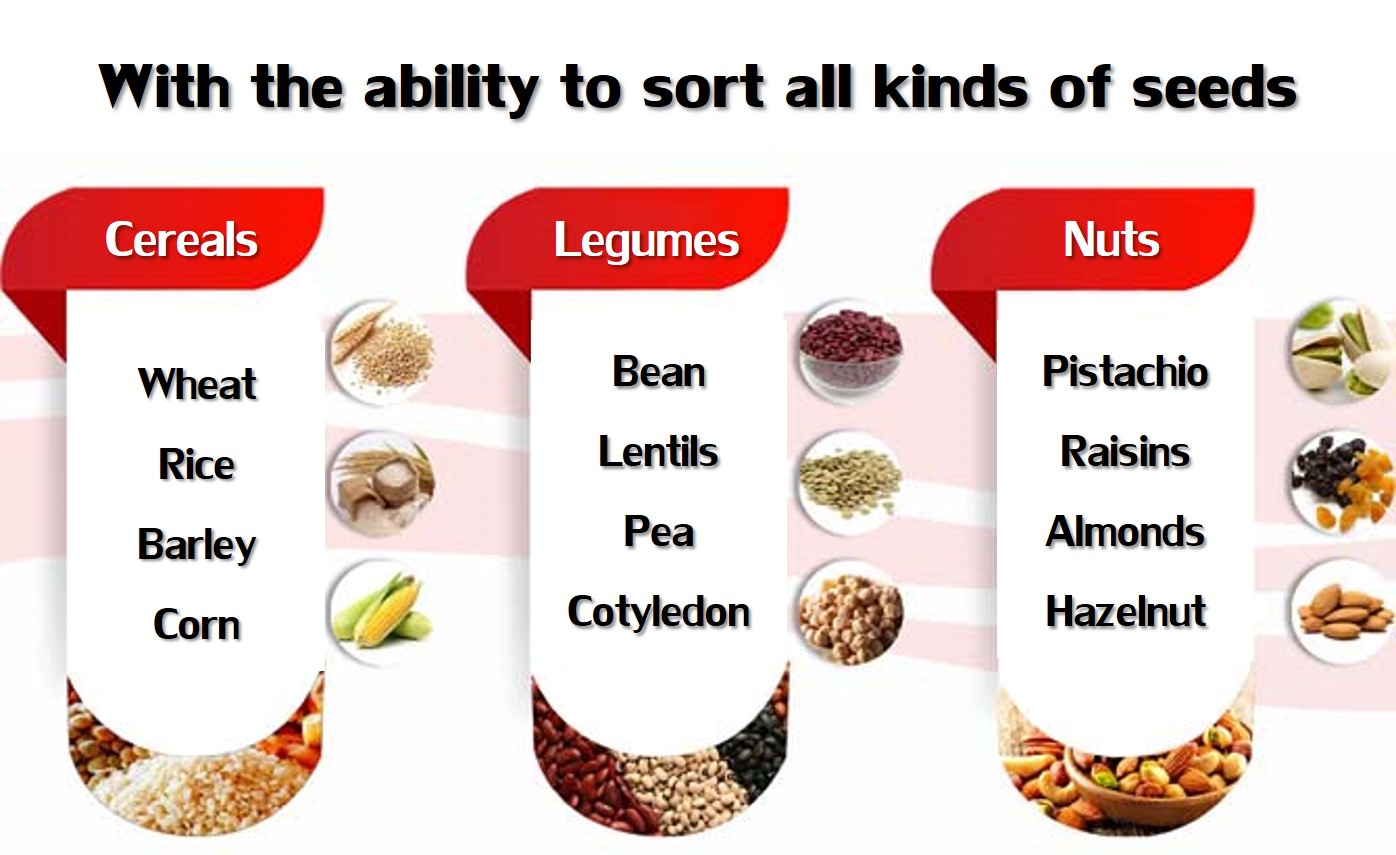

Sorting of all kinds of seeds: nuts, legumes, grains, etc.

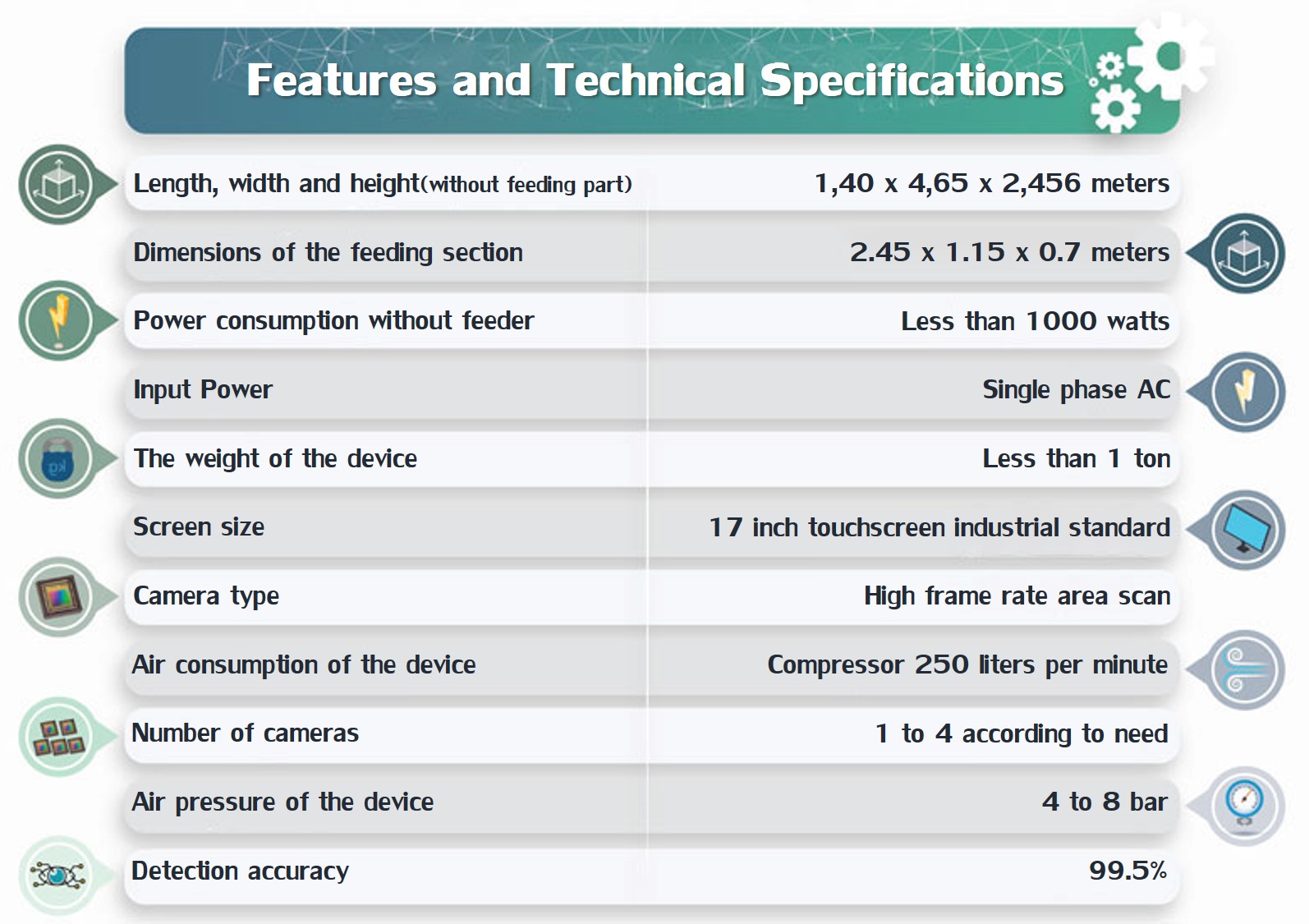

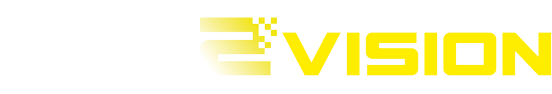

An intelligent industrial system called a "Sampi sorter" has the right parameters for classifying and uniformly sorting agricultural products as well as different kinds of seeds, nuts, and grains. The seeds are dispersed on the conveyor in this sorter by a feeder, and at the end of the course, the conveyor is quickly released. Several photos and data are prepared from each seed's face as it passes in front of the projectors, cameras, and other sensors as it is hanging in the air. Each seed is divided into two categories—good (accepted) and bad (rejected)—by the artificial intelligence and image processing of the Sampi sorter based on the size, shape, color, and morphology (stains, fractures, etc.) set by the user in the software. The suspended grains pass in front of a line consisting of dozens of compressed air nozzles that are separately controllable. The nozzles are controlled separately from the system processor and remove the rejected seeds from the main path.

Seeds move quickly on a conveyor belt. Upon reaching the end of the path, they separate from the conveyor belt and float past advanced sensors, projectors and cameras. At that point, multiple images of different sides of each seed are taken, and by processing these images, different appearance characteristics of each seed are determined.

How does this smart Sampi Sorter work?

In Sampi sorter, the products are transferred to the feeder through a conveyor or manually. With a strong blower connected to the feeder, some small pollutants such as dust, hair, and … are separated from the product being sorted. Sampi sorter feeder is designed and produced by using advanced vibrators in such a way that its speed can be adjusted to transfer the seeds to the conveyor and the seeds are continuously placed on the conveyor through the output of the feeder and with a suitable distance.

The device's capabilities in terms of function:

- Suitable for classifying a wide variety of nuts, legumes, grains, dried fruits, chips and chopped products such as potato chips, date chips and sliced onions

- Multiple software licenses for various products on a same device

- Separation and classification based on size, color, shape and morphology

- The ability to sort based on the special features of seeds (like pistachio skin and raisin stem)

- Not hitting the products unlike drop sorters

- Touch interface

- The device's body is constructed from steel plates and aluminum profiles in accordance with food industry standards

- Providing real-time statistics on the quality of cargo being sorted

- Statistical report of inputs and operations of the device

- Advanced feeder with electronic rate adjustment and equipped with special suction

- Diagnosis using laser

- Detection using image processing

- Using artificial intelligence and deep learning algorithm

- Conveyor with European food industry standard

- Remote monitoring capability

- Ease of cleaning the device

- Ability to work around the clock 24*7

- User friendly interface

- User interface software with different access levels (senior user, operator)

- No need for water

- It has an emergency shutdown key and an advanced scenario

- The input of the device is only single-phase 220 volts

- Suitable for distinguishing seed and seedless types of seeds and some fruits (dates, olives, cherries, cherries, etc.)

- The ability of UV radiation for disinfection (sterilization)

Advantages to utilizing a Sampi sorter

Based on the talent of each country, the World Trade Organization has introduced products or services that have export potential and income generation at the national level. The petrochemical industry is logical and reasonable given Iran's enormous oil and gas reserves, and its main goal is to avoid crude sales and profit from the added value of processed products; Horticulture and petrochemicals have both been proposed as possible growth factors in the Middle East. How lovely it is to view horticulture and agriculture from the same perspective. Just as we established a refinery for our oil products, we should also take the Sampi smart sorter into consideration by separating the added value of sorting from the raw sale of agricultural items. We gained from them as well.

- Inability to perform advanced sorting of superior and inferior agricultural products

- Product damage in old technology mechanical sorters

- Uncertainties in standardization and bias of load due to manual sorting and stability of sorting results

- Ability to bring produce to market quickly before quality begins to deteriorate

- Interaction issues and health issues with sorters

Meanwhile, the United Nations Food and Agriculture Organization (FAO) reports that one-third of the world's agricultural products are wasted. Moreover, in today's world, almost every 5 seconds one of them dies of hunger.