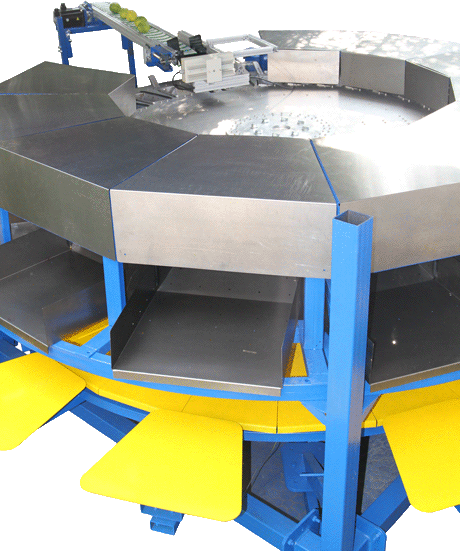

Phi Sorter

Fruits Sorter

φ sorter is a sorting machine with small size (about 4*5 ) and high efficiency, which is used in order to grade fruits, specially circle or even long fruits with less than 15 cm length. Besides the suitable size and applicability in small spaces, this sorter is also able to sort 7 fruit per second; which is equal to 5 tons per hour for some fruits like apple with an average 200 g weight. It is necessary to mention that this efficiency is completely industrial and high.

The φ(Phi) sorter is able to categorize fruits into 8 groups based on the defined features in the user interface software. A separate outlet is also considered for the other groups which are not defined. The φ (Phi) sorter would never use compact air systems (pneumatic) and water, it only uses a single-phase power supply as the input of its tasks.

The performance procedure of this sorter is as following:

The fruit will be poured into the input box and the system would automatically put the fruit on the input conveyer belt (this procedure is designed in a modular way and it is possible to provide it separately). The spreading procedure of fruit on the conveyer belt is in a way that each fruit would be placed in a predefined place and they would be separated from each other.

When the conveyer reaches the imaging sections, each fruit falls into the rotating plate of φ(Phi) sorter. It is necessary to mention that the height of this section is very low so the fruit would not be physically damaged. The fruit passes in front of the cameras, projectors and the other probably added sensors and a 360˚ image would be taken from the fruit.

After settling on the considered place, the essential calculations would be accomplished and the fruit would be categorized. And when the conveyer passes in front of the related outlet (one of the 8 predefined outlets), the operator of that outlet will be activated and pours the fruit into the considered basket.

After putting the similar fruit into each one of the outlets, a person will take the fruit and arrange them into a basket which is placed in front of him/her (this section could be optionally automatic). After being filled, the basket would be pulled to the front side and finally, it would be placed on a rotating conveyer. The baskets would be lead to the output section by the conveyer. At this level, the output baskets can be transferred to another conveyer or picked up by a person and be stored.

It should be noted that the machine measures the weight of each fruit basket and prints it on a label in text and 2D barcode together with other information including the fruit’s garden, the line manager, the fruit characteristics within the basket, the sorting time and place etc. and the user attaches it on the box. This information is very important for managing the line and tracking possible consumer complaints.

The performance of the machine:

- Appropriate for sorting different types of fruit (apples, citrus, kiwi, peaches, etc.)

- Image processing based sorting

- Color-based sorting

- Size-based sorting (radius, natural shape, etc.)

- Sorting based on the appearance defects (stain, incision, scratch, etc.)

- Weight-based sorting

- The ability of sterilization with UV radiation

The machine features:

- The ability of observing all of the fruit sides by the sensors.

- Suitable for usage in a relatively small spaces

- Industrial standard

- Low noise operation

- Non-pneumatic functionality

- No need to water

- Operation with single phase electricity

- 24/7 functionality

- The possibility of designing a washable machine

- User-friendly interface

- Economic value-added by sorting the fruit

- Reducing the production costs

- Reduction of wasted materials

- Reduction of dissatisfaction or complaints and product return

- Permanent and repeatable quality

- Production line Output and input precise controlling (production line management).

- Products health increase

- Production line analysis and reports

- The possibility of product tracking